Virtual Twin develops cars in the marketplace..Daso System

Jun 14, 2025

|

Specifically, the automobile and mobility industries around the world are now rapidly reorganizing from internal combustion engines (ICE-internal combination engines) to electric vehicles (EV-electric vehicles), and from hardware to software. While various power sources such as electric vehicles, hybrids, and hydrogen vehicles coexist, the evolution of battery technology and expansion of charging infrastructure have emerged as key challenges across the industry. In particular, next-generation batteries such as solid-state batteries, LFPs, and sodium-ion batteries secure technical competitiveness in terms of mileage, safety, and cost.

At the same time, vehicles are redefined as SDVs and their functions and values continue to expand with over-the-air (OTA) updates and autonomous driving technologies. These changes enable new services such as connected cars, smart infrastructure, and data-based maintenance, and the business model of the automobile industry is also expanding to subscription-type, mobility as a service (MaaS), and data-based personalization services.

In this time of upheaval, startups and small businesses (SMB-Small and Midsize Business) are responding nimbly by utilizing cloud-based technologies, collaboration-driven platforms, model-based systems engineering, and integrated simulation tools. In particular, cloud environments that enable flexible expansion while reducing initial capital expenditures and collaborative systems that reduce design errors and iterations are important competitive advantages for them.

Ultimately, to survive in the future mobility market, it is key to create sustainable and differentiated values based on fast response, open collaboration systems, and strong digital infrastructure beyond simple technology retention.

Recently, Volkswagen Group announced the signing of a long-term partnership to advance Volkswagen Group's digital infrastructure for state-of-the-art vehicle development through the implementation of Daso Systems' cloud-based 3D Experience platform. Volkswagen Group has chosen Daso Systems' cloud-based 3D Experience platform as its primary engineering and manufacturing platform.

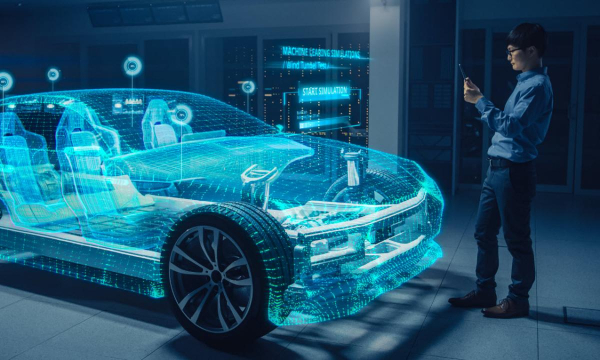

In the future, engineers, designers, and other experts from Volkswagen, Audi, and Porsche brands will utilize the Virtual Twin to simplify vehicle development. This allows Volkswagen to simulate, test, and improve all aspects of vehicle development in a collaborative virtual environment provided by Daso Systems before starting actual production, while also complying with global regulatory and sustainability standards.

Daso Systems is providing a digital integrated environment, virtual twin, and collaboration-based product lifecycle management (PLM) solution based on the 3D Experience platform to help mobility companies around the world cope with different challenges. Through this, mobility companies are strengthening their digital capabilities to respond to complex global supply chain risk mitigation as well as to quickly and flexibly develop products. In other words, it provides A to Z of Mobility.

Lawrence Montanari, vice president of Daso Systems' automotive and mobility industry, said, "Internal combustion engine cars took 50 years to develop, and electric vehicles took about 10 years. However, it now takes only two years for a new automotive platform to emerge. The development period has been drastically shortened thanks to the innovative technology of Daso System," he said, expressing confidence in his technology.

A new way of collaborating with virtual twins at the center of the 3D Experience platform is called 'Virtual Enterprise' by Daso System. This allows automakers to easily work with stakeholders around the world, no longer bound by physical constraints or barriers between organizations, to increase the sustainability of the automotive industry.

"Automakers are under pressure to deliver new products and features quickly and cost-effectively," said Lawrence Montinari, vice president. In addition, in order to create a top-notch vehicle, advanced technology solutions are needed, including the ability to integrate hardware and software development. The 3D Experience platform will be the answer."

However, Daso System's customer group is not limited to large automakers. Companies in electric trucks and high-performance racing, such as Harbinger and Peugeot Sport, which have recently attracted attention, are also using Daso Systems' solutions.

Recently, the electric vehicle market has been growing rapidly due to strengthened regulations, technological advances, and increased demand for sustainability. As of 2022, electric vehicles accounted for 10% of global new car sales, and major countries such as the EU plan to ban the sale of internal combustion locomotives by 2035. As a result, each country is focusing on expanding charging infrastructure, while startups and automobile manufacturers (OEMs) are accelerating their development of battery, charging stations, and parts technologies.

Changes in consumer perception are also driving the spread. There is a growing recognition that electric vehicles are advantageous in terms of total cost of ownership (TCO-Total Cost of Ownership), and various types of electric vehicles and niche markets (two-wheeled vehicles, three-wheeled vehicles, small commercial vehicles, etc.) are also growing rapidly. China's NIO, India's Simple Energy, and Korea's Equal are leading the market by introducing innovative services and products.

While mobility as a service (MaaS) and FaaS-Fleet-as-aS service drive innovation in smart cities and urban logistics, autonomous driving technology is also rapidly evolving around ADAS (Advanced Driver-Assistance Systems), sensors, and communication technologies. At the heart of this shift is virtual twin-based simulation technology, which simultaneously improves the speed and quality of product development.

The basis for realizing all these innovations is Daso System's cloud-based 3D Experience platform, which integrates the entire process of electric vehicle manufacturing from design to manufacturing and operating to support digital transformation and securing global competitiveness.

Although the electric truck market is still in its infancy compared to the general electric vehicle market, the need for energy-efficient and cost-effective midsize trucks is rapidly increasing due to the surge in last-mile delivery and logistics demand.

One of the companies leading this change in the industry is California-based start-ups 'Harbinger'. Harbinger is redesigning its electric vehicle-only chassis (excluding the body in the car) platform for class 4-7 mid-sized commercial vehicles (delivery trucks, trucks, school buses, camping cars, etc.). Development is underway under the goal of developing a structure optimized for electric vehicles from scratch, not just a simple internal combustion engine vehicle modification, to bring innovation to the market that remains in traditional technology.

Harbinger is developing an electric vehicle that can compete with internal combustion engine trucks by adopting a vertical integration method that develops and produces its own axles that integrate motors, inverters, and gearboxes, as well as battery systems, chassis, and drive systems.

It is Daso System's cloud-based 3D experience platform that enables this complex development process. Through the 3D Experience platform, which covers the entire process of vehicle development, including CAD design, engineering BOM, and virtual assembly, Harbinger has built an environment where team members around the world can collaborate in real time and has even secured scalability for future corporate growth.

Harbinger is also supported by Daso Systems' 3DEXPERIENCE for Startups program. For startups, instead of high-end PLM solutions that are expensive, a cloud-based 3D Experience platform that secures scalability and accessibility was an attractive option. Through this, various applications such as CATIA, ENOVIA, SIMULIA, and DELMIA can be used without burden.

Through Katia, the vehicle-wide design is integrated, and Enovia plays a central role in interdepartmental collaboration and change management. This enables agile product development, including trade-off decisions between parts, real-time feedback, and switching from engineering bills of materials (eBOM) to manufacturing bills of materials (mBOM). In particular, accurate BOM-Bill of Materials management according to various specifications of the vehicle (e.g., wheelbase, battery pack) is also key to the transition to an important production stage.

In the future, through Del Mia, Harbinger plans to expand and apply manufacturing plans, assembly jig design, and process sequence optimization, and plans to actively utilize the platform's functions in maintenance, ergonomics, and tool path planning during the vehicle's 20-year (about 720,000 km) life.

Harbinger aims to revolutionize driver experience and vehicle performance in general, not just electrification, and is setting a new benchmark for mid-size commercial electric vehicles. Harbinger will soon introduce an electric truck that will realize safe and smart eco-friendly deliveries on U.S. streets through Daso Systems' 3D Experience platform.

Chinese car and motorcycle maker Shineray Group noted consumer demand for practical and affordable new energy vehicles (NEV-New Energy Vehicles) rather than premium electric vehicles. As a result, Shine Ray Group launched the seven-seater electric SUV "SWM Giant Tiger Eddie," introducing a competitive model with a price of less than 100,000 yuan (about 20.2 million won) and a driving distance of up to 1,000 kilometers.

However, until just a few years ago, the Shinerey Group was struggling with productivity and quality control due to an inefficient material statement management system. Material statements for design, manufacturing, and service were managed by different teams, and data inconsistencies and errors occurred frequently as changes were handled manually, resulting in repeated production delays and cost losses due to rework.

To address these issues, ShineRay Group introduced Daso Systems' 3D Experience platform. Through Enovia, collaboration-based product life cycle management (PLM) was established, and existing Katia V5 design data was linked to 3D Experience using POWER'BY technology. This integrated data connections between design, software, and manufacturing departments, and changes in material statements could be immediately reflected in the design model.

In particular, Digital Mockup allows the structure of the entire vehicle to be visualized from an early stage, identifying design errors in advance and facilitating collaboration between the development team and customers. This made it possible to track product development in real-time, and design optimization was also possible.

This digital transformation has enabled ShineRay Group to respond quickly to market changes and continue to roll out new energy vehicles at reasonable prices. As a result, unlike its competitors being eliminated from the Chinese electric vehicle market due to profitability issues, Shine Lei Group has become a competitive manufacturer that combines practicality and technological efficiency.

Since the pandemic, the automotive industry has been changing at an unprecedented rate, and fundamental technological innovation is essential for sustainable growth. Uncertainty in the global economic environment, diversification of consumer needs, and the rise of new vehicle segments such as electric vehicles and hybrids, along with enhanced regulations (BS6, CAF, RDE, etc.), pose major challenges to existing manufacturing methods. As a result, manufacturing finished vehicles has a dual task of simultaneously securing complex system integration capabilities and economical new car development capabilities.

Amid these changes, it is worth paying attention to seven key trends that are reshaping the automobile industry. The first is SDV. As vehicles gradually shift to software-oriented, OTA updates, AI capabilities, and electronic architecture advancement are becoming essential elements. The second is electricity, and MBSE-based design strategies are becoming more important with the development of battery technology, and battery safety and charging infrastructure problems are required at the same time.

The third is the proliferation of autonomous driving and advanced driver assistance systems (ADAS). This increases the safety and user convenience of the vehicle, and simulation-based virtual verification technology is becoming a key tool to cope with complex road environments. The fourth is the expanded use of AI, which is applied not only to autonomous driving but also to various areas such as data analysis, design optimization, and cost prediction during the entire vehicle development process and simultaneously improves manufacturing efficiency and quality.

The fifth is model-based systems engineering (MBSE). It consistently manages data throughout the product life cycle, enabling collaboration efficiency and simplification of design structures. The sixth is a lightweight design strategy, which simultaneously realizes EV mileage improvement and carbon emission reduction through various advanced materials, optimization technologies, and AI-based design tools.

Finally, digital innovation acts as a foundation technology that integrates vehicle design, simulation, and manufacturing as a whole. The introduction of virtual twin, cloud, and machine learning-based CAE technologies is accelerating the establishment of an agile and intelligent mobility ecosystem, increasing the speed and precision of product development. The seven trends at the center of change are fundamentally reshaping the paradigm of the automobile industry, and only companies that actively embrace and lead them will be able to gain an advantage in future competition.

Editor Kim Tae-jin, tj.kim@carguy.kr

This article was translated by Naver AI translator.